了解 LED 像素灯带的终极指南

提示、技巧以及您需要了解的内容

我们经常被问到关于LED像素灯带(有时也被称为像素灯带、“智能灯带”或“智能灯带”)的问题。

大多数人想知道的第一件事就是像素灯带究竟是做什么的,以及它与标准的不可寻址LED灯带的区别。但是,关于像素灯带,仅仅这个问题的答案还远远不够。此外,在ENTTEC,我们也生产LED像素灯带,所以人们自然想知道这些产品是如何融入(市场)的。

随着我们不断增加的像素产品系列在娱乐和建筑照明行业越来越受欢迎,我们认为现在是向我们的研发团队提出一些你们最常见的问题,并给出一些专业答案来帮助你们顺利上手的好时机(特别是如果你刚刚开始灯光控制的探索之旅,那么,欢迎加入!)。

LED 像素灯带简介

什么是像素灯带?

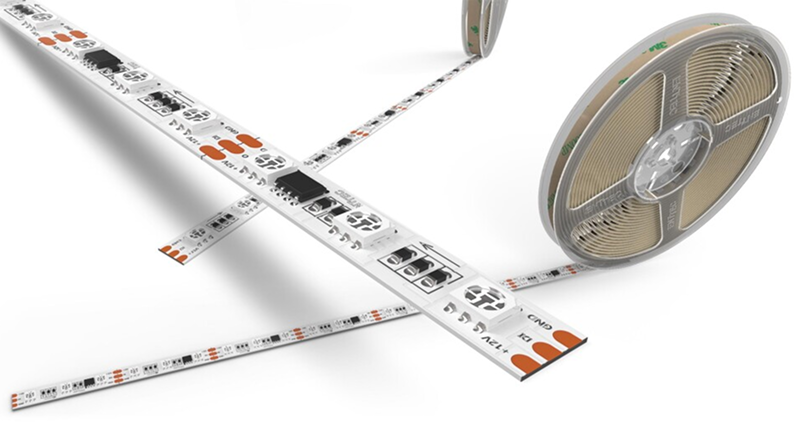

像素灯带是一种柔性印刷电路板(PCB),上面布满了多色的、可寻址的表面贴装(SMD)发光二极管(LEDs)。

这种电路板通常带有背胶,这有助于快速便捷地安装。

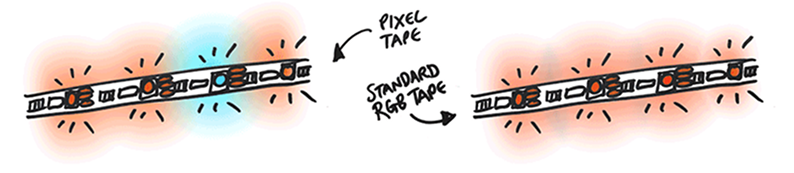

与标准的RGB灯带不同,像素灯带的每个LED都有其自己的芯片,这使得它能够被单独控制做出相应反应(例如:改变颜色、关闭等)。

这些被称为可寻址LED。像素灯带仍然可以完成不可寻址灯带所能做的一切……而且还能做更多。

设计您的系统

虽然我们在这里主要关注像素灯带,但如果我们不至少提及一下像素点光源,那就不是ENTTEC的风格了。

当涉及像素点和灯带时,这两种产品都易于安装并且有一定程度的功能相似性,那么你应该选择哪一种呢?

答案将取决于您预期的应用场景以及您用于创建该场景的可用空间。

请考虑以下几点:

使用灯带的优点

- 稳定且均匀的光线

- 轻巧便携

- 相较于像素点,占用的物理空间更少

- 在散光罩下容易做到不显眼

- 适合预算有限的临时性安装

使用像素点的优点

- 比灯带更高的防水级别

- 作为一个显著的特色更具视觉吸引力

- 更大的光输出量

- 坚固耐用:耐磨且使用寿命更长

- 无需挤压(成型)操作,也不存在热管理方面的问题

- 几乎可以安装成任何能想象到的形状

- 有多种多样的设计可供选择

无论你决定选用哪一种(像素灯带或像素点),在开始你的项目之前,都有几条基本原则是你应该认真考虑的。

首先,请记住每个项目都是独一无二的。

你想要购买的像素产品会因多种因素而有所不同,这些因素包括(但不限于)美观性、使用环境以及可用空间等。

所以在你掏出辛苦挣来的钱之前,好好考虑一下以下几点:

- 该项目需要什么样的风格?

- LED灯带将会被安装在哪里?

- LED灯带将被安装在什么物体的表面上或者内部?

为什么我应该选用ENTTEC灯带而不是其他品牌的呢?

ENTTEC灯带是在澳大利亚设计制造的,其设计旨在超越全球行业标准,而不仅仅是符合这些标准。

我们把使用比市面上其他灯带更好的基板和更厚的铜材作为我们的使命。

我们的灯带按照最高标准制造,之后由我们的工程师团队进行质量检查和测试,以确保与我们广受欢迎的像素控制器系列实现最佳兼容性。

更厚的铜线路能提供更强的耐用性、更好的散热性能以及更优的电流传导,所有这些对于打造出尽可能优质的产品而言都是至关重要的因素。

尤其是在涉及高密度灯带时,散热是一个关键的安全问题,所以我们十分重视在我们的灯带中所使用的铜材量。

劣质印刷电路板(PCB)通常每平方英尺的铜厚度约为一盎司,而我们一般要求我们的灯带使用的铜量是这个数值的三倍。

所以,选择ENTTEC,你可以尽管放心了。

最后,不管你最终选用了哪种产品,永远不要忘记……

所有的像素灯带都应该由合格的电工来安装!

疑问与解答

选择 5V 还是 12V 的灯带?

这取决于最终用户的使用场景。

12V 意味着 3 个发光二极管(LED)组成一个像素,而 5V 是每个 LED 为一个像素。但功率消耗是相同的。

由于5V像素灯带的压降,其颜色变化比12V灯带更为明显。因此,12V灯带能够实现的最大连续长度要比5V灯带更长。然而,12V灯带的功耗比5V灯带卷的功耗更高。

所以,在购买之前最好先计算并了解您的系统所能提供的功率情况。

RGB灯带和RGBW灯带相比怎么样?我该选哪种呢?

这同样取决于最终用户的使用场景。

RGB像素灯带采用三合一颜色(红、绿、蓝)的LED芯片。

当红、绿、蓝三种颜色都达到最亮时,终端用户可以得到近乎白色的光。

RGB灯带每个LED还使用3个通道,这意味着在进行映射时,所需的DMX通道数会更少。

RGBW像素灯带拥有一个四合一颜色(红、绿、蓝、白)的LED芯片。

尽管RGB(红绿蓝)灯带能够产生接近白色的颜色,但RGBW像素灯带中专门的白色LED可以提供更纯正的白色色调。

RGBW灯带每个LED使用4个通道,这意味着在对灯带进行映射时需要更多的DMX通道。

每条像素灯带包含多少个DMX通道呢?

它之所以被称为像素灯带,是因为它可以将灯带上面的每一个点都视作是RGB的独立组合。

- 1个像素 = 3个DMX通道(RGB)

- 1个像素 = 4个DMX通道(RGBW)

由于灯带的LED密度不同、长度也不同,你可以将这些因素综合起来计算,从而得出各种各样的结果。例如:

- (8PL30) 30 RGB LEDs/米 灯带 x 5 米/卷 = 150 个像素 (150 个像素 x 3) = 450 通道

- (8PL30) 30 RGB LEDs/米 灯带 x 5 米/卷 = 150 个像素 (150 个像素 x 3) = 450 通道

- (8PL60) 60 RGB LEDs/米 灯带 x 5 米/卷 = 300 个像素 (300 个像素 x 3) = 900 通道

- (8PL144) 144 RGB LEDs/米 灯带 x 2 米/卷 = 288 个像素 (288 个像素 x 3) = 864 通道

- (8PX30) 30 RGBW LEDs/米 tape x 5 米/卷 = 150 个像素 (150 个像素 x 4) = 600 通道

- (8PX60) 60 RGBW LEDs/米 tape x 4 米/卷 = 240 个像素 (240 个像素 x 4) = 960 通道

- (8PL60) 60 RGB LEDs/米 灯带 x 5 米/卷 = 300 个像素 (300 个像素 x 3) = 900 通道

- (8PL144) 144 RGB LEDs/米 灯带 x 2 米/卷 = 288 个像素 (288 个像素 x 3) = 864 通道

- (8PX30) 30 RGBW LEDs/米 tape x 5 米/卷 = 150 个像素 (150 个像素 x 4) = 600 通道

- (8PX60) 60 RGBW LEDs/米 tape x 4 米/卷 = 240 个像素 (240 个像素 x 4) = 960 通道

便于记住的要点:

- 170 个RGB 像素 = 510 DMX通道 = 1 DMX 域

- 128 RGBW 像素 = 512 DMX 通道= 1 DMX 域

我们的产品每个端口最多可驱动 2U:

| 产品 | RGB 像素 | RGBW 像素 |

| Pixie Driver | 170 | 128 |

| Pixelator | 340 | 256 |

| Pixelator Mini | 340 | 256 |

| Pixelator Mini PX1-8D | 340 | 256 |

| PSAT | 340 | 256 |

| Pixel Port | 340 | 256 |

哪种类型的表面适合安装像素灯带?

像素灯带应安装在干净、干燥的表面上。在安装之前,请先用干净的布蘸酒精清洁该表面。

表面应具有导热性,以便让灯带能够充分散热。

查看ENTTEC公司的型材产品,了解能实现最佳性能的理想表面(注意:这些产品目前在欧洲无法购买)。

表面不应有纹理,也不应是低表面能材料。

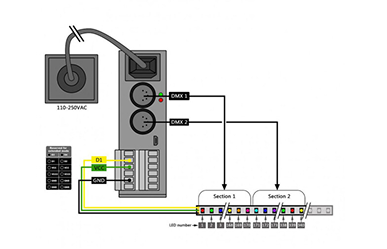

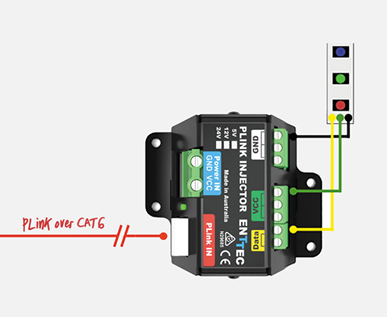

我该如何用Plink驱动器连接像素灯带呢?

像这样:

为什么当灯带发出白色光时,灯带末端的LED灯会呈现暖白色/粉红色呢?

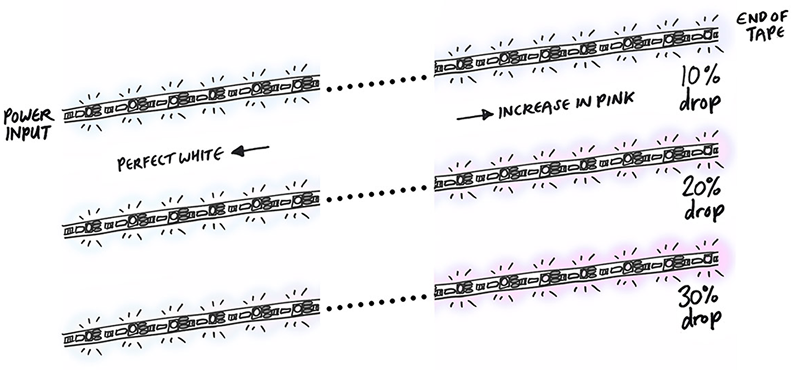

出现这种情况是因为在尝试为较长的灯带供电时,沿着LED灯带存在压降。由于电压降的缘故,当灯带发出白色光时,沿灯带的像素颜色会逐渐发生变化。

最好在压降开始产生影响之前(x米处)确定可能的最大运行长度,并每隔x米接入电源。

沿着一串白色LED灯,电压下降得越厉害,离电源最远的那些LED灯就会呈现出越明显的粉红色调。随着电压降低,整个灯带的亮度也会略微下降。

同样,人眼对这些现象的感知程度自然因人而异,但大多数人会觉得颜色变化几乎难以察觉。

(请注意:上述图示并非旨在成为精确的科学图表。它只是一种简单的直观呈现,旨在让您大致了解当出现不同百分比的压降时,您有时可能会观察到的那种效果。)

大多数灯带和灯珠呈现这些现象的程度都非常细微,而其他一些可能会稍微明显一些。

我从亚马逊/阿里巴巴/诚实鲍勃超级廉价折扣照明仓库(Honest Bob’s Super-Cheap Discount Lighting Warehouse™)采购了一些像素灯带。它能与ENTTEC的像素器/精灵驱动器配合使用吗?

这将取决于所购灯带的协议以及所涉及的布线方式。有两种不同类型的布线:三线或四线灯带。所有ENTTEC的像素控制器仅支持三线灯带。

ENTTEC的Pixie驱动器支持以下协议:

- 9PDOT-8bit

- WS2811, WS2812, WS2812B

- APA-104 LEDs

ENTTEC的Pixelator和Pixelator Mini支持以下协议:

- 9PDOT-8bit

- 9PDOT-16bit

- WS2811, WS2812, WS2812B, WS2813

- SK6812

- TM1804

- TM1812

- APA-104 LEDs

请注意:9PDOT协议仅由修订版B(2017年起销售的设备)支持。

可能存在其他与安特泰克所支持协议类似的LED协议。我们不敢声称能支持所有协议,但如果您碰巧发现了一种能正常使用但未列在此处的协议,请告知我们,以便我们更新相关文档。

为什么我的像素灯带末端会闪烁?

出现这种情况是因为在尝试为过长的灯带供电时,LED灯带沿线存在电压降。由于压降的影响,灯带末端的像素会出现闪烁现象。最好在压降开始产生影响之前(x米处)确定可能的最大运行长度,并每隔x米接入电源。